Nylon macrame cord material analysis reveals the extraordinary capabilities of this synthetic powerhouse, demonstrating why professional crafters and industrial artisans consistently choose nylon for projects demanding uncompromising strength, exceptional flexibility, and long-term reliability. As the crafting world evolves toward high-performance materials, nylon emerges as the undisputed champion of synthetic fibers, offering characteristics that surpass traditional options while opening new possibilities for innovative design applications.

This comprehensive guide explores the revolutionary world of nylon macrame cord material analysis, uncovering the scientific principles that make this synthetic fiber the preferred choice for demanding applications requiring superior performance under extreme conditions. From its remarkable elasticity to its outstanding abrasion resistance, nylon macrame cord delivers consistent results that enable crafters to push creative boundaries without material limitations.

The engineering excellence behind nylon macrame cord material analysis demonstrates how advanced polymer science translates into practical benefits for contemporary crafters seeking materials that can withstand challenging conditions while maintaining aesthetic appeal. Understanding these fundamental properties empowers artisans to select appropriate materials for specific applications while maximizing project success through informed material choices.

Modern crafting demands have elevated nylon macrame cord material analysis to essential knowledge for serious practitioners who recognize that material selection directly impacts project outcomes, longevity, and overall satisfaction. This synthetic marvel combines the best aspects of engineered performance with practical workability, creating opportunities for artistic expression that were previously impossible with traditional materials.

Understanding Nylon Macrame Cord Material Analysis Fundamentals

Molecular Engineering and Polymer Structure

Nylon macrame cord material analysis begins with understanding the polyamide molecular structure that creates exceptional strength characteristics through hydrogen bonding between polymer chains. This unique chemical architecture produces fibers with remarkable tensile strength that often exceeds natural alternatives while maintaining the flexibility essential for complex macrame applications.

The crystalline and amorphous regions within nylon macrame cord material analysis reveal how controlled manufacturing processes create fibers with predictable performance characteristics. These microscopic structures work together to provide the balance of strength and elasticity that makes nylon ideal for applications requiring both load-bearing capacity and dynamic movement.

Advanced spinning techniques used in nylon macrame cord material analysis enable manufacturers to orient polymer molecules in specific directions, creating fibers with enhanced strength properties along their primary axis. This molecular alignment ensures that nylon cord performs consistently under stress while maintaining dimensional stability throughout extended use periods.

The hydrogen bonding network inherent in nylon macrame cord material analysis provides natural memory characteristics that help fibers return to their original configuration after stretching. This property ensures that nylon macrame projects maintain their intended shape and tension over time, reducing the need for frequent adjustments or repairs.

Physical and Chemical Properties Excellence

Nylon macrame cord material analysis demonstrates exceptional resistance to abrasion and wear, making it ideal for applications where repeated contact or friction occurs. This durability characteristic ensures that nylon projects maintain their appearance and structural integrity even in high-traffic or frequently handled installations.

The chemical resistance profile of nylon macrame cord material analysis shows excellent performance against oils, greases, and most organic solvents that would degrade other materials. This chemical stability makes nylon suitable for industrial applications and challenging environments where exposure to various substances is unavoidable.

Moisture absorption characteristics within nylon macrame cord material analysis create dynamic properties that change with environmental conditions, allowing the material to adapt to humidity levels while maintaining structural integrity. This hygroscopic behavior can be advantageous in applications where dimensional stability under varying moisture conditions is important.

Temperature performance data from nylon macrame cord material analysis reveals excellent stability across wide temperature ranges, with nylon maintaining its properties from extreme cold to moderately high heat conditions. This thermal stability makes nylon suitable for outdoor applications and environments with significant temperature variations.

Types and Manufacturing Variations

Nylon 6 versus Nylon 66 Analysis

Nylon macrame cord material analysis distinguishes between Nylon 6 and Nylon 66 compositions, each offering specific advantages for different applications. Nylon 6 provides enhanced flexibility and easier processing characteristics, while Nylon 66 delivers superior strength and temperature resistance for demanding applications.

The molecular structure differences revealed through nylon macrame cord material analysis show how manufacturing processes affect final fiber properties. These variations allow crafters to select specific nylon types that match their project requirements while optimizing performance for intended applications.

Processing conditions during nylon macrame cord material analysis production significantly impact final fiber characteristics, with controlled cooling rates and draw ratios determining strength, elongation, and texture properties. Understanding these manufacturing variables helps crafters appreciate why different nylon cords exhibit varying performance characteristics.

Quality control measures in nylon macrame cord material analysis ensure consistent properties throughout production runs, eliminating the variations that might compromise project integrity. This manufacturing precision creates reliable materials that perform predictably across different batches and production periods.

Denier Classifications and Performance Ratings

Denier ratings in nylon macrame cord material analysis indicate the linear density of fibers and directly correlate with strength and flexibility characteristics. Higher denier nylon cords provide greater load-bearing capacity while lower denier options offer enhanced flexibility and easier manipulation for detailed work.

The relationship between denier and nylon macrame cord material analysis performance helps crafters select appropriate materials for specific applications. Understanding these correlations ensures optimal material selection that matches project requirements while maximizing performance potential.

Multi-filament construction techniques used in nylon macrame cord material analysis combine numerous fine fibers to create cords with exceptional strength and smooth handling characteristics. This construction method produces superior knot-holding ability while maintaining the flexibility needed for complex macrame patterns.

Texturized nylon options revealed through nylon macrame cord material analysis provide enhanced grip and handling comfort while maintaining the strength characteristics that make nylon special. These specialty constructions offer alternatives for crafters seeking improved workability without sacrificing performance.

Working with Nylon Macrame Cord

Preparation and Handling Techniques

Preparing nylon macrame cord material analysis specimens for crafting involves understanding the unique characteristics that distinguish nylon from other synthetic alternatives. The natural elasticity of nylon requires specific handling techniques to prevent over-stretching during preparation while taking advantage of its remarkable flexibility.

Pre-stretching procedures in nylon macrame cord material analysis help identify the working limits of the material while removing initial elongation that occurs under first loading. This preparation step ensures that finished projects maintain their intended dimensions and proportions over time.

Heat-setting techniques can be applied to nylon macrame cord material analysis to create permanent shapes and configurations that would be impossible with other materials. Careful temperature control allows crafters to pre-form cord sections for specialized applications or artistic effects.

The memory properties inherent in nylon macrame cord material analysis help maintain knot tension over extended periods, reducing the maintenance requirements associated with materials that relax or stretch under continuous load. This characteristic ensures long-term project stability with minimal intervention.

Advanced Knotting and Assembly Methods

Nylon macrame cord material analysis reveals optimal knotting techniques that take advantage of the material’s unique properties while avoiding potential problems associated with high-strength synthetic fibers. The smooth surface of nylon requires specific knot configurations that provide adequate holding power without slippage.

Dynamic loading considerations in nylon macrame cord material analysis become important for applications where sudden forces or impacts might occur. Understanding how nylon responds to shock loading helps crafters design projects that can safely handle unexpected stress concentrations.

The elasticity characteristics revealed through nylon macrame cord material analysis enable unique design possibilities that take advantage of nylon’s ability to stretch and recover. These properties allow for dynamic installations that respond to environmental forces while maintaining structural integrity.

Joining techniques for nylon macrame cord material analysis require specific methods that accommodate the synthetic nature of the material while ensuring permanent, reliable connections. These specialized techniques prevent the separation problems that might occur with inappropriate joining methods.

Specialized Applications and Performance Scenarios

High-Stress and Load-Bearing Applications

Nylon macrame cord material analysis demonstrates exceptional performance in high-stress applications where material failure could have serious consequences. The predictable strength characteristics of nylon provide confidence for load-bearing installations that must support significant weights safely and reliably.

Safety factor calculations based on nylon macrame cord material analysis data help crafters design projects with appropriate margins of safety for their intended applications. Understanding these engineering principles ensures that nylon projects perform safely throughout their intended service life.

Dynamic loading scenarios covered in nylon macrame cord material analysis reveal how the material responds to repeated stress cycles and varying load conditions. This information proves crucial for applications like hammocks, swings, or other items that experience regular movement and load changes.

Fatigue resistance properties demonstrated through nylon macrame cord material analysis show how the material maintains its strength characteristics even after millions of stress cycles. This durability makes nylon ideal for applications where long-term reliability under repetitive loading is essential.

Outdoor and Environmental Applications

Weather resistance characteristics revealed through nylon macrame cord material analysis demonstrate superior performance compared to many natural alternatives when exposed to UV radiation, moisture, and temperature extremes. This environmental stability makes nylon excellent for outdoor installations requiring long-term durability.

UV degradation testing in nylon macrame cord material analysis shows how different nylon formulations respond to solar exposure, with some grades providing years of outdoor service without significant strength loss. Understanding these variations helps crafters select appropriate materials for sun-exposed applications.

Marine environment performance data from nylon macrame cord material analysis reveals excellent resistance to salt water and marine organisms that quickly destroy other materials. This capability makes nylon suitable for boat applications and coastal installations where salt exposure is inevitable.

Freeze-thaw cycling effects studied in nylon macrame cord material analysis demonstrate how the material maintains flexibility and strength even after exposure to extreme temperature variations. This characteristic ensures reliable performance in climates with significant seasonal temperature changes.

Industrial and Commercial Applications

Heavy-duty installations utilizing nylon macrame cord material analysis data require materials that can perform reliably under continuous stress while maintaining their appearance in professional environments. Nylon’s combination of strength and aesthetic appeal makes it suitable for commercial applications.

Safety compliance requirements addressed through nylon macrame cord material analysis ensure that installations meet relevant standards for public spaces and commercial environments. Understanding these requirements helps crafters create projects that satisfy both aesthetic and regulatory demands.

Maintenance considerations based on nylon macrame cord material analysis show how synthetic materials can reduce long-term operational costs through extended service life and reduced replacement requirements. This economic advantage makes nylon attractive for budget-conscious commercial applications.

Quality assurance protocols derived from nylon macrame cord material analysis provide frameworks for ensuring consistent performance in critical applications. These procedures help maintain reliability standards essential for commercial and industrial uses.

Maintenance and Longevity Strategies

Cleaning and Care Protocols

Maintaining nylon macrame cord material analysis specimens requires understanding how cleaning processes affect synthetic fiber properties while preserving performance characteristics. Proper cleaning techniques ensure that nylon projects maintain their appearance and strength throughout their service life.

Chemical compatibility data from nylon macrame cord material analysis guides selection of appropriate cleaning agents that effectively remove soil and stains without damaging the synthetic fiber structure. This information prevents cleaning-related damage that might compromise project integrity.

Drying procedures based on nylon macrame cord material analysis recommendations prevent heat damage while ensuring complete moisture removal that could lead to mold or mildew problems. Proper drying techniques maintain material properties while preventing deterioration.

Inspection protocols derived from nylon macrame cord material analysis help identify wear patterns and potential problems before they become serious issues. Regular assessment enables proactive maintenance that extends project life while ensuring continued safe operation.

Long-term Storage and Protection

Storage environment requirements established through nylon macrame cord material analysis ensure that unused cord and completed projects maintain their properties during extended storage periods. Proper storage conditions prevent degradation while preserving material characteristics.

UV protection strategies based on nylon macrame cord material analysis data help prevent photodegradation during storage and display periods. Understanding these requirements enables crafters to protect their investments while maintaining project appearance.

Temperature control considerations derived from nylon macrame cord material analysis prevent thermal damage during storage while maintaining material flexibility and strength characteristics. Proper temperature management ensures that stored materials remain ready for use.

Contamination prevention protocols based on nylon macrame cord material analysis protect stored materials from chemicals, oils, and other substances that might compromise fiber properties. These procedures ensure that stored nylon maintains its performance characteristics.

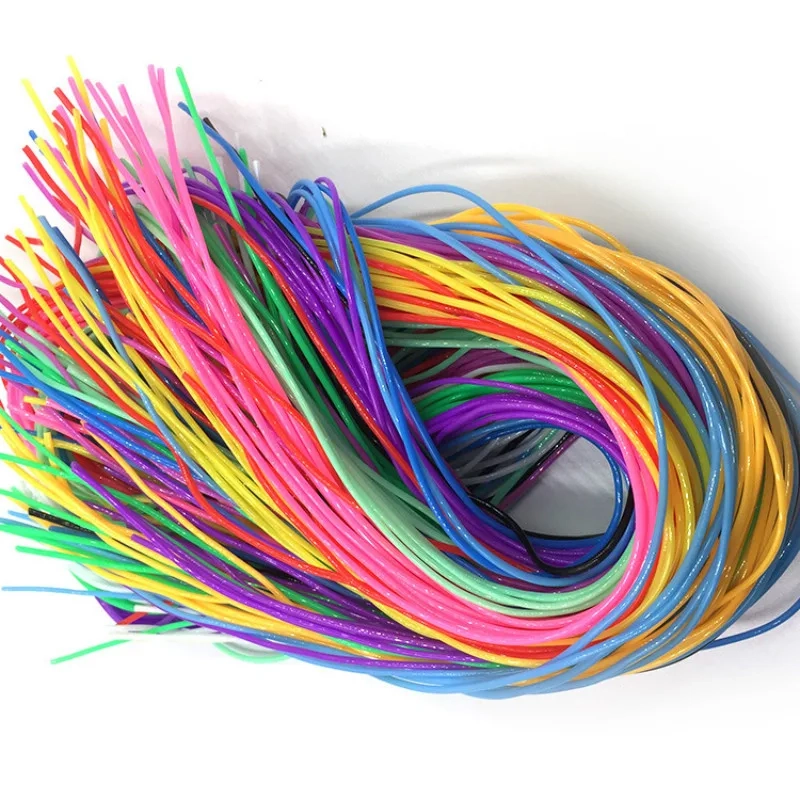

Colorful Braided Rope PVC Braided Wire Plastic

Elevate your jewelry making projects with this vibrant collection of 120 colorful braided ropes, perfect for creating stunning necklaces, bracelets, and countless other DIY accessories. These high-quality PVC braided wires combine durability with eye-catching colors, providing the ideal foundation for both beginner and advanced jewelry crafting projects.

Frequently Asked Questions

How does nylon macrame cord material analysis compare to other synthetic alternatives in terms of strength and flexibility characteristics?

Nylon macrame cord material analysis reveals superior performance characteristics compared to polyester and polypropylene alternatives, particularly in applications requiring high strength combined with significant elasticity. While polyester offers excellent UV resistance and dimensional stability, nylon provides approximately 20-30% greater tensile strength and significantly better shock absorption capabilities due to its ability to stretch up to 30% before breaking. This elasticity makes nylon ideal for dynamic applications like hammocks or exercise equipment where energy absorption is crucial. However, nylon’s hygroscopic nature means it absorbs moisture and can lose some strength when wet, unlike polyester which maintains consistent properties regardless of moisture content. The choice between materials depends on specific application requirements, with nylon excelling in high-stress, dynamic applications while polyester performs better in static, weather-exposed installations.

What are the key considerations for working with nylon macrame cord material analysis data when selecting appropriate cord types for specific projects?

Nylon macrame cord material analysis data reveals several critical factors that influence material selection for optimal project outcomes. Denier rating directly impacts both strength and flexibility, with higher denier cords providing greater load-bearing capacity but reduced flexibility for detailed knotwork. Environmental conditions significantly affect nylon performance, as UV exposure gradually degrades strength while moisture absorption can cause dimensional changes and temporary strength reduction. Temperature ranges affect nylon differently than other synthetics, with excellent low-temperature flexibility but potential softening at elevated temperatures above 200°F. The intended stress levels determine whether standard nylon is sufficient or whether high-tenacity grades are necessary for safety-critical applications. Additionally, the dynamic versus static loading profile influences cord selection, as nylon’s elasticity provides advantages in shock-loading scenarios but may cause unwanted stretch in applications requiring precise dimensional control.

What maintenance and care procedures are essential for preserving nylon macrame cord material analysis specimens and finished projects over extended periods?

Nylon macrame cord material analysis indicates specific maintenance requirements that differ from natural fibers due to the synthetic polymer structure and hygroscopic properties. Regular cleaning with mild detergents removes accumulated soil and oils that can accelerate UV degradation, while avoiding harsh chemicals or excessive heat that might damage the polymer chains. Proper drying after cleaning or moisture exposure prevents the development of mold or mildew while avoiding heat sources that could cause thermal damage. UV protection becomes crucial for outdoor applications, with periodic inspection for signs of photodegradation including surface fuzzing, color changes, or strength loss. Storage conditions should maintain stable temperatures and humidity levels while protecting against contamination from oils, solvents, or other chemicals that could weaken the fiber structure. Load-bearing applications require periodic inspection for wear patterns, knot slippage, or stress concentration points that might indicate the need for maintenance or replacement before failure occurs.

Conclusion

Nylon macrame cord material analysis demonstrates the exceptional capabilities of this synthetic powerhouse, revealing why it stands as the ultimate choice for applications demanding superior strength, flexibility, and long-term reliability. The comprehensive examination of nylon’s molecular structure, performance characteristics, and application versatility establishes it as an indispensable material for serious crafters and professionals who refuse to compromise on quality or performance.

The detailed analysis reveals that nylon macrame cord material analysis provides unmatched advantages in strength-to-weight ratio, elasticity, and durability that make it suitable for everything from delicate artistic installations to heavy-duty industrial applications. As crafting requirements continue to evolve toward more demanding performance standards, nylon emerges as the intelligent choice for projects that must deliver consistent results while withstanding challenging conditions that would compromise lesser materials.